Another name for the copper stretching machine is the wire stretching machine. In fact, this device can be called one of the most widely used traction devices in various industries, including the electrical industry, the automotive industry, and also the recycling industry. With the help of this device, the length of the wire can be increased and its diameter can be reduced with the help of the molds in the device in a controlled manner.

In this article, we will introduce you to the operation of the copper stretching device and its applications. If you don’t have enough information about this device, it’s better to stay with us in the rest of this article to learn more about its uses and how it works, as well as the purchase price of the copper stretching device.

How does the copper stretching machine work?

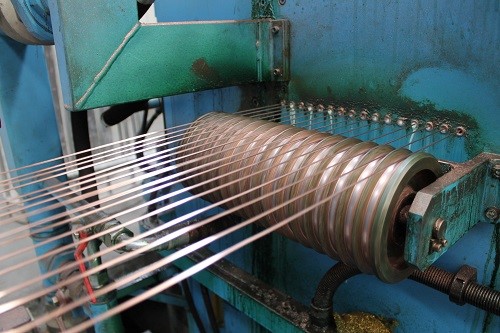

The way this device works is very simple. In this way, first the copper wire is installed at the entrance of the device and then it is guided inside the device through a rotating roller. Rollers and rotating pulleys make the wire enter into the wire tensioning device, and finally, after making changes to the diameter of the wire, it exits from the other side of the device through the rotating pulleys.

The molds in the machine are adjustable and the operator can set these molds in large or small diameters. Finally, the diameter of the wire is adjusted according to the mold and it becomes uniform. Of course, it should be noted that this device not only changes the diameter of the wire, but also increases its hardness and resistance; Therefore, the wire becomes smaller in diameter and obtains a higher quality.

Applications of copper stretching device/wire stretching device

Among the applications of this device, we can mention the production of all kinds of metal rails. The production of coated wire is also done with the help of copper stretching machine. In fact, with the help of this device, the production cost and time can be saved a lot. In addition, as we said, the quality of the wire also increases. This machine is also widely used for making wire for automotive and aviation industries. On the other hand, this machine is also very useful for making copper wires from recycled wires. Among the applications of the copper stretching device, the following can be mentioned.

Making all kinds of copper wires and cables

With the help of the molds used in this device, copper wires can be stretched to a controlled size and they can be made ready for making all kinds of copper wires and cables.

Making all kinds of screws and motors

All kinds of copper coils can be prepared with the help of this device. All you need is a copper drawing machine with different molds so that you can prepare all kinds of coils with its help.

Making electrical parts

To make all kinds of metal parts that are used in the electronics industry, copper metal resistors and some special coils are needed, which can be easily produced with the help of this device.

Making a spring

With the help of the copper stretching device, you can prepare different types of springs that are used for the automotive industry or electronic industries. This device has the ability to make metal wires in the form of springs and with different sizes.

Application of copper stretching device in waste industry and recycling of non-ferrous metals

Non-ferrous metals such as copper, which have excellent malleability, are very resistant to corrosion and rust, and their weight is also very light. Due to its non-magnetic properties, copper metal is perfect for wiring and electronic circuits. These wires can be easily prepared to enter the market again with the help of the copper stretching device. As we have mentioned in the above cases and in the applications of using the copper stretching device, you can prepare different types of recycled wires with the help of this device and present them to the market.

Copper stretching machine parts

The parts of the wire tensioning machine or copper tensioning machine include the body of the machine, gearbox and dynamo of the machine, drum, pulley, magic and tension molds. The drawing dies are usually of the three common types of tungsten carbide, diamond or tool steel, among these three types, tungsten carbide and synthetic diamond are mostly used for wire drawing. Regarding the parts of the device, you should also know that the parts are mounted on top of each other on the metal body of the device.

The body size of the device varies depending on the type and size of the device. This size can reach up to about 1 meter by 6 meters for large devices. The number of drums in the devices is also different. Some machines are single drum and some may have up to 8 drums. The traction power of the device is related to the size of the drum and depends on the power of the gearbox and dynamo; Therefore, the greater the power of these parts in the device, the greater the final power of the device will be, and some devices may withstand the pressure of several tons.

What effect does the copper stretching device have on increasing the efficiency of the recycling industry?

By compressing and improving the quality of the wire, this device makes the recycled copper ready to enter the production cycle again. Many times, with the help of this machine, it is possible to produce all kinds of recycled copper cables and coils, and instead of sending the copper to the recycling factory, it can be directly injected into the market.

What budget is needed to buy a copper stretching machine in metal recycling?

Wire tensioning devices are produced in different sizes and sizes, and their predominant type is also different and they are priced accordingly. Some of these devices are also suitable for stretching steel wires, and naturally their rates are higher; Therefore, after classifying your needs in the market industry and determining your workload, you can also choose the right type of device.